|

|

wilson benesch a.c.t. 3zeroFibonacci Series 2.5-Way Floor Standing Speaker

Pricing From NZD $79,990

|

DESCRIPTION

The name A.C.T. is an acronym for ‘Advanced Composite Technology’ – it is a reference to the composite technologies upon which the Wilson Benesch brand was founded and subsequently has become synonymous with. The A.C.T. acronym was first used in 1991 for the company’s first loudspeaker, the A.C.T. One. The technology was subsequently used in the ‘A.C.T. Two’, the ‘A.C.T.’, the ‘A.C.T. C60’ and in the previous generation A.C.T. One Evolution. The new A.C.T. 3Zero, therefore, follows a long line of speakers, embodying the heritage of the Wilson Benesch brand and the classic A.C.T. design. This heritage plays a significant role in how the speaker sounds. Some enthusiasts that have studied the lineage use the analogy that perhaps the A.C.T. One Evolution is to Wilson Benesch what the 911 is to Porsche. A design that has been slowly honed, improved, evolved over many generations. Worked on by many talented people over decades of paying attention to the finest details, receiving customer feedback, incorporating new technologies as they become available, constantly refining the design to the point where the product becomes an icon.

Similar physical proportions have been retained, however, the A.C.T. 3Zero marks a significant advance in the materials that are used to create the composite monocoque that forms the largest single component in any Fibonacci Series loudspeaker. The new biocomposite A.C.T. 3Zero Monocoque is made from naturally sourced, renewable and sustainable materials replacing almost all materials previously used that had been sourced from petrochemical sources. In terms of performance, the new monocoque is superior to its predecessor both in terms of damping and stiffness, leaving the new upgraded drive technologies free from cabinet colouration to deliver a new reference from the A.C.T. marquee.

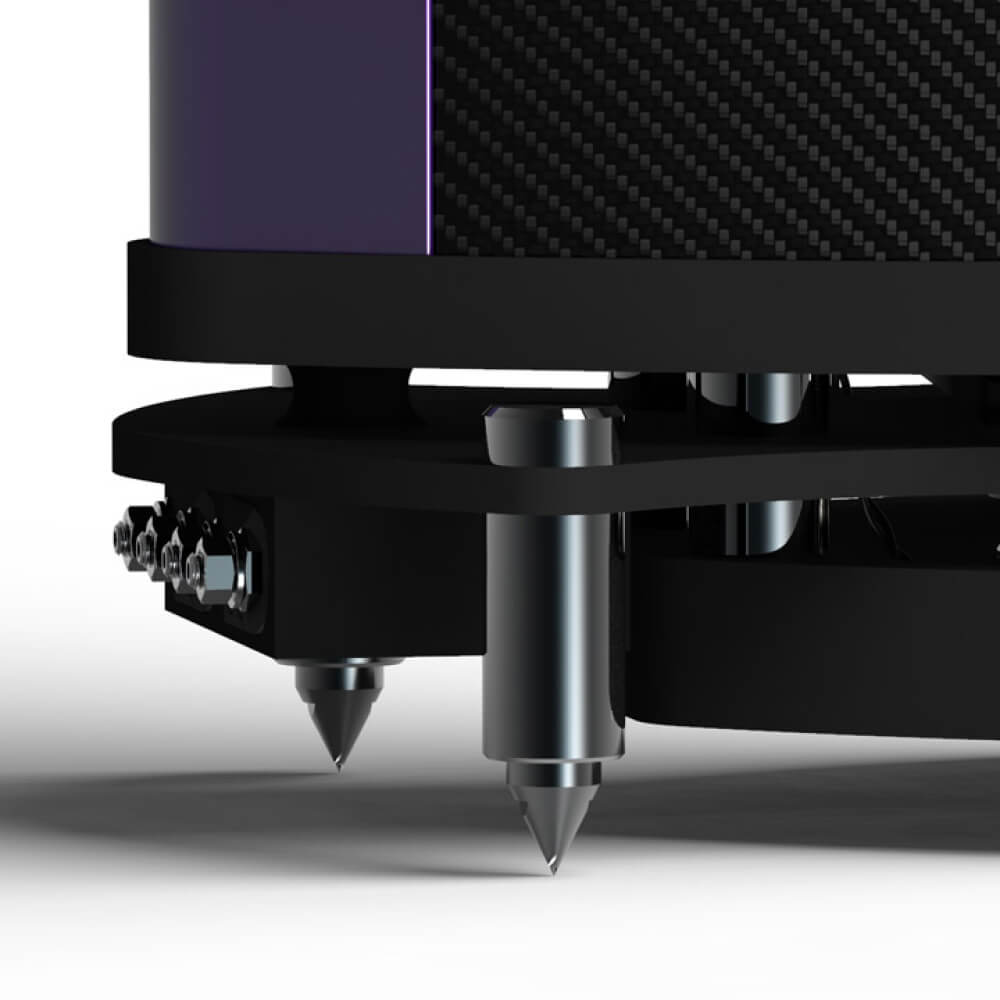

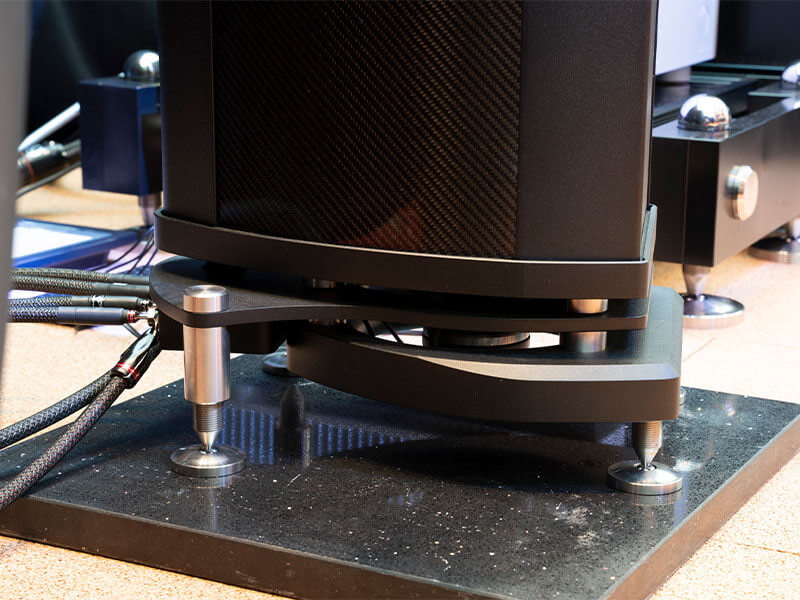

The new A.C.T. 3Zero also marks the first time in history that an A.C.T. loudspeaker has been fitted with an Isobaric Drive System. The new A.C.T. 3Zero incorporates the IDS within the elegant, highly engineered three-part foot. Joining the Isobaric is a low-bass Tactic 3.0, the new Fibonacci Tweeter and a dedicated Tactic 3.0 midrange drive unit which is directly amplifier coupled. This reductive approach to crossover design eliminates phase anomalies and aberrations associated with complex crossovers, creating the shortest and purest signal pathway possible. This approach to design can be heard when you listen to a Wilson Benesch loudspeaker, the natural acoustic character, multi-layered detailed but natural timbre and the deep but integrated soundstage from the top to the bottom of the frequency band.

The new Tactic 3.0 drivers and the new Fibonacci Tweeter are directly from the flagship Eminence loudspeaker as is the Troika system featured in this remarkable speaker. When you sit in front of a pair of A.C.T. 3Zero, you are experiencing the results of that famous lineage, the outcome of thousands of hours over many years that people have spent fussing over all aspects of the design (most that you can’t see). There is an immediate sense that the speaker is very accomplished, a serious, mature speaker made by people who have been doing this for a long time. In the true Wilson Benesch tradition, this speaker simply disappears and allows the music to flow, imparting very little of its own character into the presentation, which even at this level is very rare.

Although there are a few models in the Wilson Benesch range that take these design elements to a more extreme level, the A.C.T. 3Zero can be considered a true destination speaker. It is a bold statement of expert engineering, manufacturing and craftsmanship that now defines Wilson Benesch. A pure high-end audio thoroughbred.

Similar physical proportions have been retained, however, the A.C.T. 3Zero marks a significant advance in the materials that are used to create the composite monocoque that forms the largest single component in any Fibonacci Series loudspeaker. The new biocomposite A.C.T. 3Zero Monocoque is made from naturally sourced, renewable and sustainable materials replacing almost all materials previously used that had been sourced from petrochemical sources. In terms of performance, the new monocoque is superior to its predecessor both in terms of damping and stiffness, leaving the new upgraded drive technologies free from cabinet colouration to deliver a new reference from the A.C.T. marquee.

The new A.C.T. 3Zero also marks the first time in history that an A.C.T. loudspeaker has been fitted with an Isobaric Drive System. The new A.C.T. 3Zero incorporates the IDS within the elegant, highly engineered three-part foot. Joining the Isobaric is a low-bass Tactic 3.0, the new Fibonacci Tweeter and a dedicated Tactic 3.0 midrange drive unit which is directly amplifier coupled. This reductive approach to crossover design eliminates phase anomalies and aberrations associated with complex crossovers, creating the shortest and purest signal pathway possible. This approach to design can be heard when you listen to a Wilson Benesch loudspeaker, the natural acoustic character, multi-layered detailed but natural timbre and the deep but integrated soundstage from the top to the bottom of the frequency band.

The new Tactic 3.0 drivers and the new Fibonacci Tweeter are directly from the flagship Eminence loudspeaker as is the Troika system featured in this remarkable speaker. When you sit in front of a pair of A.C.T. 3Zero, you are experiencing the results of that famous lineage, the outcome of thousands of hours over many years that people have spent fussing over all aspects of the design (most that you can’t see). There is an immediate sense that the speaker is very accomplished, a serious, mature speaker made by people who have been doing this for a long time. In the true Wilson Benesch tradition, this speaker simply disappears and allows the music to flow, imparting very little of its own character into the presentation, which even at this level is very rare.

Although there are a few models in the Wilson Benesch range that take these design elements to a more extreme level, the A.C.T. 3Zero can be considered a true destination speaker. It is a bold statement of expert engineering, manufacturing and craftsmanship that now defines Wilson Benesch. A pure high-end audio thoroughbred.

FEATURES

Bio-composite Monocoque Cabinet (‘Bio-Carbon’)

The new A.C.T. 3Zero bio-composite Monocoque is superior to its predecessor both in terms of damping and stiffness by orders of magnitude. Furthermore, it features a variety of natural materials that are derived from sustainable and renewable sources, realising Wilson Benesch’s goal to create more natural, renewable and sustainable materials technologies. In terms of acoustic performance, there is simply no other cabinet material used in speaker production today that comes close to this revolutionary material. All data is verified and measured through Wilson Benesch’s academic partner in the SSUCHY Project, the FEMTO Institute in Besancon France.

Advanced Cabinet Design

Further to the bio-composite material, the cabinet’s curved form is a result of significant research. The geometric form of the cabinet negates standing waves by reducing the number of flat surfaces on the loudspeaker external surface area. Therefore, any sound waves in the listening space that interact with the surface of the A.C.T. Monocoque are diffracted across a wide angle and thus diminished. As a result, such distortions are impossible for the ear to detect, allowing the loudspeaker to disappear within the listening space. This acoustic ‘stealth’ quality of the loudspeaker creates a wide open and life like soundstage.

Tactic 3.0 Drive Unit

The structure at the centre of the diaphragm plays a critical role in the behaviour of the drive unit. In the Tactic 3.0 driver, Wilson Benesch added the Fibonacci Element. Produced in house using additive manufacturing technology, the Fibonacci Element can be printed according to pre-designed parameters. Such is the precision of the additive manufacturing software, that the Wilson Benesch design team can see in cross-section and design three-dimensionally the optimal layup of carbon fibre and nylon, defining both stiffness and weight across the structure. The result is a new geometrical form that is comprised of a double curvature with both open and closed aspects in the form of a lattice structure again borrowed from natural geometry. 5 different materials and adhesives provide significant improvements in both the accuracy of the frequency response and the reduction of distortion. This is a critical aspect of the relationship between the drive unit and its ability to integrate with the roll-off of the tweeter and bass drive units. In the past, several materials have been drawn upon to enable the fine-tuning of this marriage. Additive Manufacturing has opened up a new chapter in the pursuit of this subtle but extremely important aspect of loudspeaker design. For the first time, the principal aspects of this structure can all be adjusted in a way that was previously impossible.

Fibonacci Silk-Carbon Hybridised Tweeter

The latest iteration of Wilson Benesch tweeter technology builds upon the Semisphere tweeter design pushing it into the next generation. As with all Wilson Benesch designs, the advances of the previous generation are built upon an iterative research and development pathway. With the Fibonacci tweeter, advances have been made within the structures adjacent to the motor and the hybridised dome. The Fibonacci tweeter faceplate is formed from a carbon fibre – nylon composite structure creating a geometrically optimised structure – the Fibonacci Element – that has been inspired by sacred geometry found in nature. In terms of acoustic performance, the faceplate delivers a new benchmark in terms of flat frequency response and ultrawide dispersion. In addition, the Fibonacci Element is decoupled from the motor and tweeter chassis which almost entirely eliminates structural borne resonance within this critical structure that surrounds the tweeter dome.

Isobaric Drive System

The principal low-frequency load of all loudspeakers in the Fibonacci Series is delivered by the Isobaric Drive System. Here two Tactic 3.0 Drive Units combine to create an Isobaric Drive System which is responsible for reproducing an incredibly tight and controlled bass response that is perfectly integrated with all other woofers in the loudspeaker chassis, particularly the midrange Tactic 3.0 drive unit. This system is faster and exhibits far less distortion than the large bass drive units often used by speaker manufacturers.

Direct Midrange Drive Unit Coupling

Wilson Benesch started development of its own drive unit diaphragms, including those made from a carbon fibre/epoxy matrix in 1995. Research was conducted using alternative hard dome materials. Without exception, Isotactic Polypropylene was favoured for its natural sound and the ability of this material to absorb energy and avoiding complex breakup modes in the diaphragm. This critical material characteristic allows the Wilson Benesch design team to achieve mechanically and acoustically what would otherwise be implemented in complex crossover designs with a series of inductors and capacitors. This reductive approach to crossover design maintains phase, linearity and the degree of control over manufacturing and design of both the drive unit specifications and the enclosure air volume allows Wilson Benesch to eliminate all crossover components in the midrange drive units of most Fibonacci Series models running the drive unit directly amplifier coupled.

Precision CNC Machined Foot

One of the most important principles in structural engineering is loading. All modern buildings are built upon solid foundations. It is the reference point for everything above it, transferring the load of the structure into the ground. Within loudspeaker design, it is crucial to create a stable point from which the drive units can propagate complex and accurate waveforms that we appreciate as music. The A.C.T. 3Zero foot is constructed from three separate precision CNC machined elements. The design not only houses the powerful Isobaric Drive System, but it also adds mass low in the loudspeaker chassis and provides structural fixing points for 13mm steel ties to fix into. These steel ties run the length of the loudspeaker chassis and tie into the loudspeaker top.

13mm Steel Ties: Compression In The Vertical Axis

The Endeavour 3Zero enclosure is held under tons of compressive force using 13mm threaded steel bars. The steel bars run the length of the enclosure and the integrated stand. They tie the large precision machined aluminium foot into the elegant base plate and in turn into the Endeavour 3Zero top plate. These vertical steel ties exert tons of compressive force in the vertical axis where the first resonant modes will emerge.

High Precision Inductors

The sound quality of a loudspeaker depends upon the quality of the components in the critical signal path. Wilson Benesch incorporate high precision, high packing ratio, Rocksolid, air core inductors in this application as well as computer controlled high precision wound inductors manufactured in-house.

Engineered for you

Every Wilson Benesch loudspeaker is hand built for you. In addition to their standard finish, they offer a range of Premium Natural Wood Veneers, Premium P1 Carbon Fibre and Premium Paint Finishes. Want to create something unique? Contact AG Lifter to create something truly unique to you. This level of individualisation just adds that something special to the ownership experience of these premium pieces.

The new A.C.T. 3Zero bio-composite Monocoque is superior to its predecessor both in terms of damping and stiffness by orders of magnitude. Furthermore, it features a variety of natural materials that are derived from sustainable and renewable sources, realising Wilson Benesch’s goal to create more natural, renewable and sustainable materials technologies. In terms of acoustic performance, there is simply no other cabinet material used in speaker production today that comes close to this revolutionary material. All data is verified and measured through Wilson Benesch’s academic partner in the SSUCHY Project, the FEMTO Institute in Besancon France.

Advanced Cabinet Design

Further to the bio-composite material, the cabinet’s curved form is a result of significant research. The geometric form of the cabinet negates standing waves by reducing the number of flat surfaces on the loudspeaker external surface area. Therefore, any sound waves in the listening space that interact with the surface of the A.C.T. Monocoque are diffracted across a wide angle and thus diminished. As a result, such distortions are impossible for the ear to detect, allowing the loudspeaker to disappear within the listening space. This acoustic ‘stealth’ quality of the loudspeaker creates a wide open and life like soundstage.

Tactic 3.0 Drive Unit

The structure at the centre of the diaphragm plays a critical role in the behaviour of the drive unit. In the Tactic 3.0 driver, Wilson Benesch added the Fibonacci Element. Produced in house using additive manufacturing technology, the Fibonacci Element can be printed according to pre-designed parameters. Such is the precision of the additive manufacturing software, that the Wilson Benesch design team can see in cross-section and design three-dimensionally the optimal layup of carbon fibre and nylon, defining both stiffness and weight across the structure. The result is a new geometrical form that is comprised of a double curvature with both open and closed aspects in the form of a lattice structure again borrowed from natural geometry. 5 different materials and adhesives provide significant improvements in both the accuracy of the frequency response and the reduction of distortion. This is a critical aspect of the relationship between the drive unit and its ability to integrate with the roll-off of the tweeter and bass drive units. In the past, several materials have been drawn upon to enable the fine-tuning of this marriage. Additive Manufacturing has opened up a new chapter in the pursuit of this subtle but extremely important aspect of loudspeaker design. For the first time, the principal aspects of this structure can all be adjusted in a way that was previously impossible.

Fibonacci Silk-Carbon Hybridised Tweeter

The latest iteration of Wilson Benesch tweeter technology builds upon the Semisphere tweeter design pushing it into the next generation. As with all Wilson Benesch designs, the advances of the previous generation are built upon an iterative research and development pathway. With the Fibonacci tweeter, advances have been made within the structures adjacent to the motor and the hybridised dome. The Fibonacci tweeter faceplate is formed from a carbon fibre – nylon composite structure creating a geometrically optimised structure – the Fibonacci Element – that has been inspired by sacred geometry found in nature. In terms of acoustic performance, the faceplate delivers a new benchmark in terms of flat frequency response and ultrawide dispersion. In addition, the Fibonacci Element is decoupled from the motor and tweeter chassis which almost entirely eliminates structural borne resonance within this critical structure that surrounds the tweeter dome.

Isobaric Drive System

The principal low-frequency load of all loudspeakers in the Fibonacci Series is delivered by the Isobaric Drive System. Here two Tactic 3.0 Drive Units combine to create an Isobaric Drive System which is responsible for reproducing an incredibly tight and controlled bass response that is perfectly integrated with all other woofers in the loudspeaker chassis, particularly the midrange Tactic 3.0 drive unit. This system is faster and exhibits far less distortion than the large bass drive units often used by speaker manufacturers.

Direct Midrange Drive Unit Coupling

Wilson Benesch started development of its own drive unit diaphragms, including those made from a carbon fibre/epoxy matrix in 1995. Research was conducted using alternative hard dome materials. Without exception, Isotactic Polypropylene was favoured for its natural sound and the ability of this material to absorb energy and avoiding complex breakup modes in the diaphragm. This critical material characteristic allows the Wilson Benesch design team to achieve mechanically and acoustically what would otherwise be implemented in complex crossover designs with a series of inductors and capacitors. This reductive approach to crossover design maintains phase, linearity and the degree of control over manufacturing and design of both the drive unit specifications and the enclosure air volume allows Wilson Benesch to eliminate all crossover components in the midrange drive units of most Fibonacci Series models running the drive unit directly amplifier coupled.

Precision CNC Machined Foot

One of the most important principles in structural engineering is loading. All modern buildings are built upon solid foundations. It is the reference point for everything above it, transferring the load of the structure into the ground. Within loudspeaker design, it is crucial to create a stable point from which the drive units can propagate complex and accurate waveforms that we appreciate as music. The A.C.T. 3Zero foot is constructed from three separate precision CNC machined elements. The design not only houses the powerful Isobaric Drive System, but it also adds mass low in the loudspeaker chassis and provides structural fixing points for 13mm steel ties to fix into. These steel ties run the length of the loudspeaker chassis and tie into the loudspeaker top.

13mm Steel Ties: Compression In The Vertical Axis

The Endeavour 3Zero enclosure is held under tons of compressive force using 13mm threaded steel bars. The steel bars run the length of the enclosure and the integrated stand. They tie the large precision machined aluminium foot into the elegant base plate and in turn into the Endeavour 3Zero top plate. These vertical steel ties exert tons of compressive force in the vertical axis where the first resonant modes will emerge.

High Precision Inductors

The sound quality of a loudspeaker depends upon the quality of the components in the critical signal path. Wilson Benesch incorporate high precision, high packing ratio, Rocksolid, air core inductors in this application as well as computer controlled high precision wound inductors manufactured in-house.

Engineered for you

Every Wilson Benesch loudspeaker is hand built for you. In addition to their standard finish, they offer a range of Premium Natural Wood Veneers, Premium P1 Carbon Fibre and Premium Paint Finishes. Want to create something unique? Contact AG Lifter to create something truly unique to you. This level of individualisation just adds that something special to the ownership experience of these premium pieces.

VIDEOS

AWARDS

REVIEWS

What Hi-Fi, 2023

"Judge these speakers by hi-fi criteria such as tonal balance, stereo imaging or detail resolution and they ace the test. Judge them on the ability to communicate the emotion in music, and they are similarly successful. Given a suitably talented system, these Wilson Benesch A.C.T. 3Zero are easily among the finest speakers we’ve ever tested. Wilson Benesch… we salute you."

SoundStage! Australia, Edgar Kramer, 2021

"The Wilson Benesch A.C.T. One Evolution is an intellectually stimulating loudspeaker. I mean that both in terms of its intelligent engineering across all aspects of its design and in the way it presents music. It has a way of engaging you in a manner that makes you think about what you’re listening to. Other designs may draw you in and engulf you in sheer emotive bliss. The A.C.T. One Evolution is capable of that too, however, it also engages your neurons on a cerebral level. At least that was my experience. Exceptional engineering aside, it’s also an aesthetically attractive design which has been meticulously constructed and flawlessly finished. The A.C.T. One Evolution loudspeakers force you to take notice. That is a lot to think about. And feel. Go on, engage your senses…"

Music Emotion, Werner Ero, 2019

"Trying to describe the sound of this speaker with typical audiophile parameters is of no real use because of the almost 1:1 sense of scale and rich live experience. Everything is there and everything is in perfect balance. Just like it needs to be, but is seldom experienced with hifi.... Together, music and system form a wonderful unity and it makes me think this is how high end music playback should be sounding, totally forgetting all technicalities and be one with the music."

HiFi+, Alan Sircom, 2015

"The A.C.T. One Evolution is the distillation of all the engineering and materials science development that Wilson Benesch can throw at a loudspeaker. Of course, 20 years later, there is a lot more loudspeaker history and engineering to throw around, and where the original A.C.T. One began ‘tabula rasa’, the A.C.T. One Evolution draws upon drive unit and high compression cabinet construction derived from two decades of loudspeaker design... I don’t want to get carried away by the bass. There is a lot more to this loudspeaker than bottom end. It’s just that the loudspeaker does bass so well, and so deep: that unbraced cabinet makes it TARDIS like and far bigger on the inside than you’d expect and that means more cabinet volume and that means more bass – but the level of control the A.C.T. One Evolution has over that bass is insane."

A.C.T. 3zero loudspeakers at the bristol show

product specifications

Type

2.5-way Floor Standing Loudspeaker

Measurements

Impedance: TBA

Sensitivity: TBA

Frequency Response: TBA

Drive Technology

Tweeter: 1x 25mm (1”) Wilson Benesch Fibonacci Hybrid Silk-Carbon Tweeter

Midrange: 1x 170mm(7″) Wilson Benesch Tactic 3.0

Mid Bass: 1x 170mm(7″) Wilson Benesch Tactic 3.0

Isobaric Drive System: 2x 170mm (7”) Wilson Benesch Tactic 3.0 in Clamshell Formation

Crossover Technology

Tweeter: Second-Order, 5kHz High Pass Filter

Midrange: Directly Amplifier Coupled

Mid Bass: First-Order

Isobaric Drive System: First-Order 500Hz Low Pass Filter

Enclosure Technology

Materials: A.C.T. 3Zero – Advanced Bio-composite Monocoque Technology, Poly-Alloy, Hybridised Construction

Tweeter: Labyrinth Sealed Tweeter Backplate

Midrange: Reflex Port Tuned with Laminar Flow Guide

Mid Bass: Infinite Baffle Sealed Enclosure

Isobaric Enclosure: Infinite Baffle Sealed Enclosure

Finishes

Dimensions

Height: 1,132mm (44.57″)

Width: 194mm (7.64″) Baffle / 276mm (10.87″) Widest Point of Foot

Depth: 376mm (14.8″)

Weight

TBC

Terminations

Bi-wirable terminal located on the loudspeaker foot at ground level

2.5-way Floor Standing Loudspeaker

Measurements

Impedance: TBA

Sensitivity: TBA

Frequency Response: TBA

Drive Technology

Tweeter: 1x 25mm (1”) Wilson Benesch Fibonacci Hybrid Silk-Carbon Tweeter

Midrange: 1x 170mm(7″) Wilson Benesch Tactic 3.0

Mid Bass: 1x 170mm(7″) Wilson Benesch Tactic 3.0

Isobaric Drive System: 2x 170mm (7”) Wilson Benesch Tactic 3.0 in Clamshell Formation

Crossover Technology

Tweeter: Second-Order, 5kHz High Pass Filter

Midrange: Directly Amplifier Coupled

Mid Bass: First-Order

Isobaric Drive System: First-Order 500Hz Low Pass Filter

Enclosure Technology

Materials: A.C.T. 3Zero – Advanced Bio-composite Monocoque Technology, Poly-Alloy, Hybridised Construction

Tweeter: Labyrinth Sealed Tweeter Backplate

Midrange: Reflex Port Tuned with Laminar Flow Guide

Mid Bass: Infinite Baffle Sealed Enclosure

Isobaric Enclosure: Infinite Baffle Sealed Enclosure

Finishes

- Standard – Textured Black

- Premium Natural Wood Veneer

- Premium Paint Finishes

- Premium P1 Carbon Fibre Finishes

- Isobaric Drive System Finishes

Dimensions

Height: 1,132mm (44.57″)

Width: 194mm (7.64″) Baffle / 276mm (10.87″) Widest Point of Foot

Depth: 376mm (14.8″)

Weight

TBC

Terminations

Bi-wirable terminal located on the loudspeaker foot at ground level